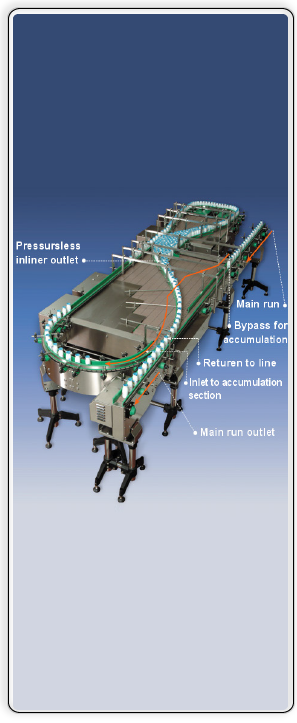

Accumulation Line

![]()

- O.L.D.A -On Line Dynamic Accumulation

In packing lines the loose products are being conveyed between dedicated machines.

|

|

|

INTERSLAT - e-mail: info@interslat.org

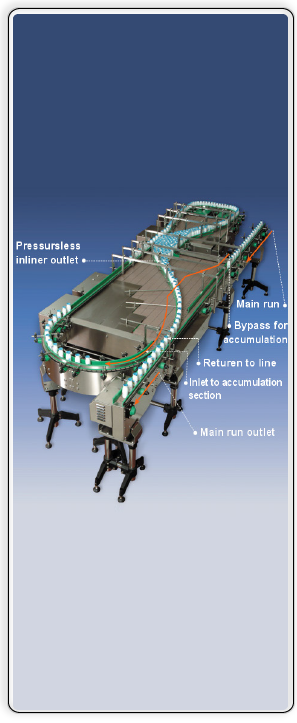

Accumulation Line

![]()

- O.L.D.A -On Line Dynamic Accumulation

In packing lines the loose products are being conveyed between dedicated machines.

|

|

|

INTERSLAT - e-mail: info@interslat.org